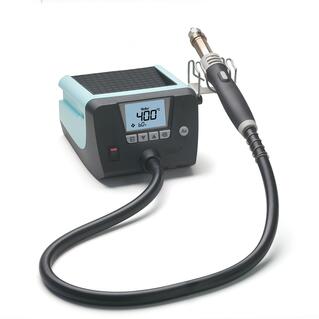

Find your perfect Rework equipment from Weller

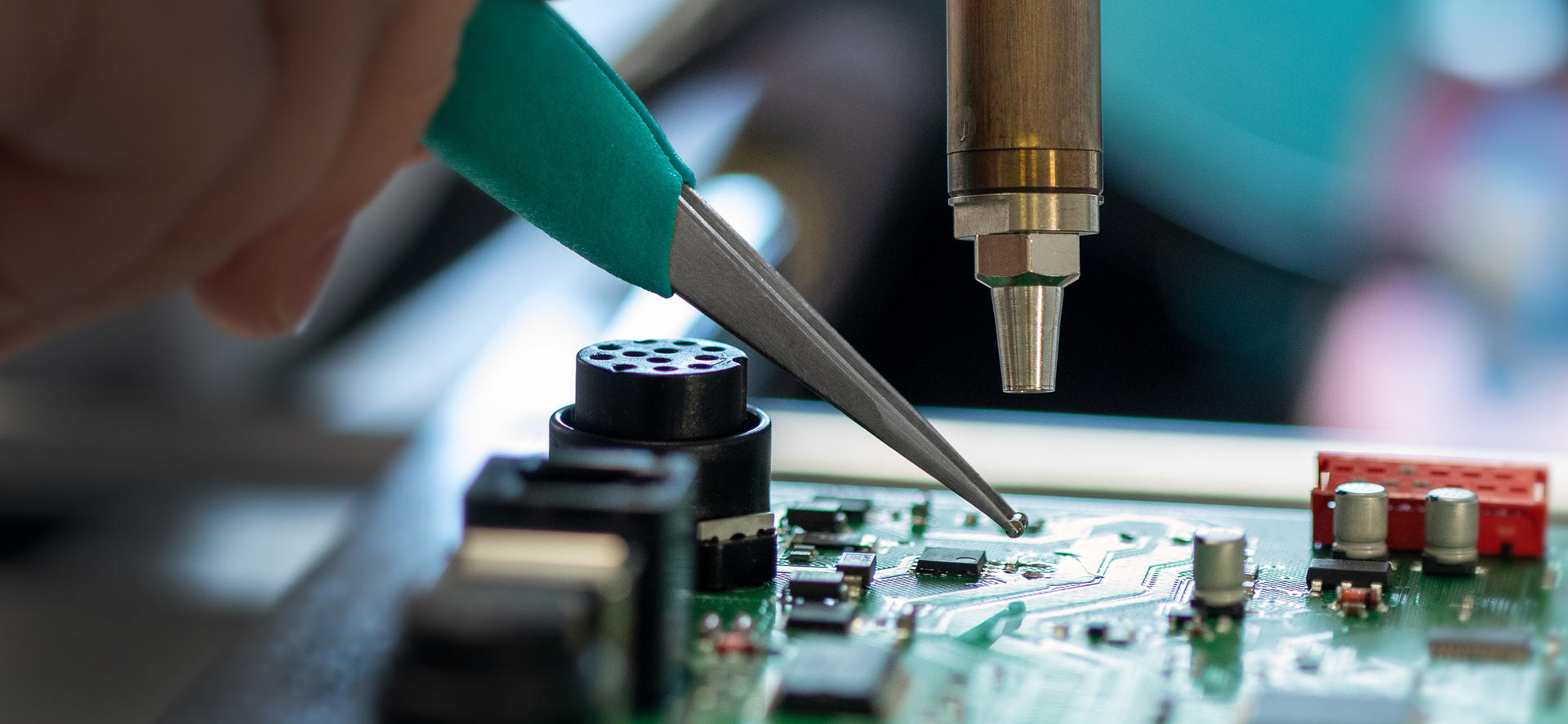

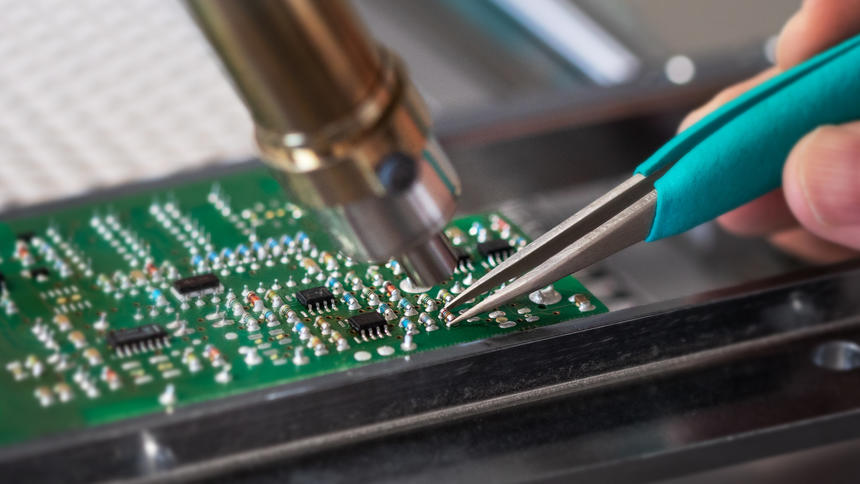

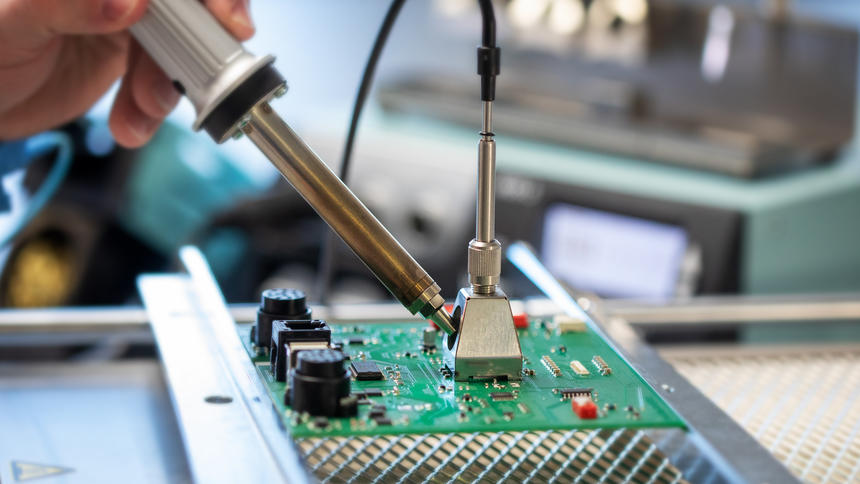

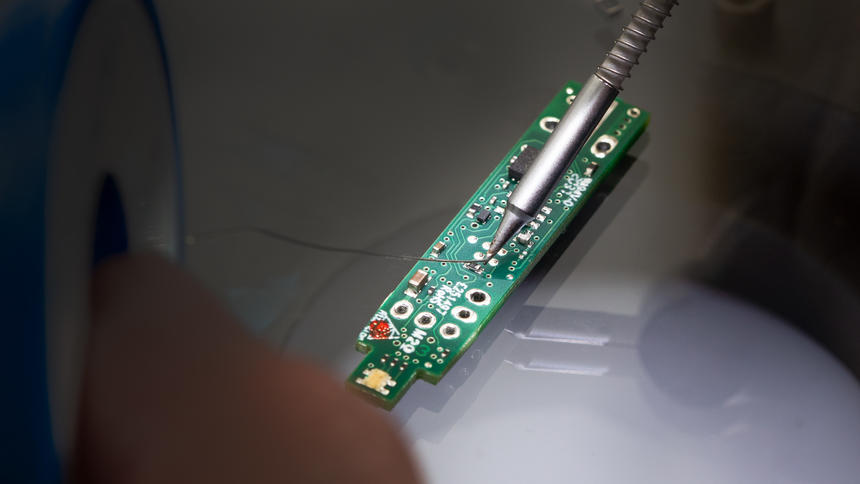

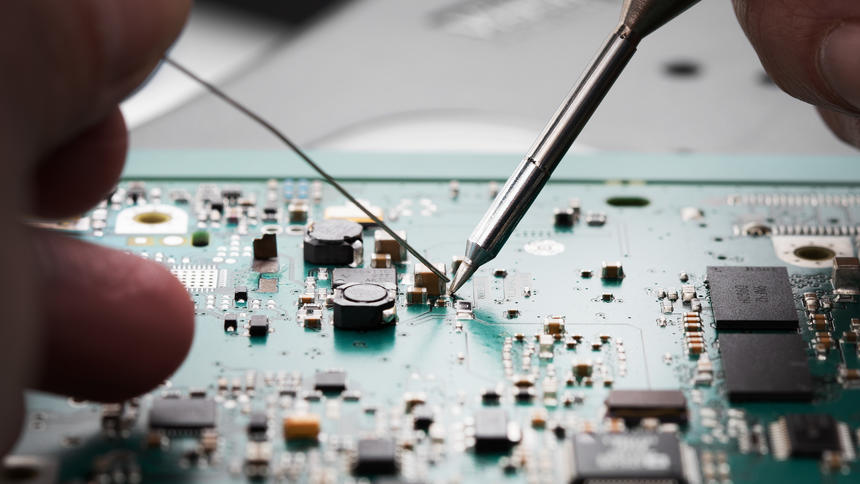

Printed circuit boards assemblies have strongly changed in the last years, with smaller components and thermally heavier boards. On top of this, lead-free soldering alloys are usually adding complexity to the process. It's crucial having everything is needed to correctly run a rework procedure without risks.

Weller's rework stations, desoldering stations and hot-air stations are specially designed for professional repair work on electronic assemblies - for industrial production technology, for the repair sector and for laboratory work. With rework stations, hot-air stations and desoldering irons from Weller you are well-equipped to run your rework procedures like reballing, de-soldering, hot air and soldering processes. Are you ready?