WTBR 1000 - Benchtop Robot

More than half a century of experience in soldering and superiority in innovation, allows us to take our customers to the next step in achieving production excellence. The new WTBR 1000 Benchtop Robot represents a one-of-a-kind synergy of precision, reliability, and productivity of soldering tasks.

Robotic Soldering Advantages at a glance

Highest soldering precision and superior reliability

- The WTBR 1000 is equipped with Weller‘s high performance Technology Line soldering tools, ensuring consistent quality of solder joints.

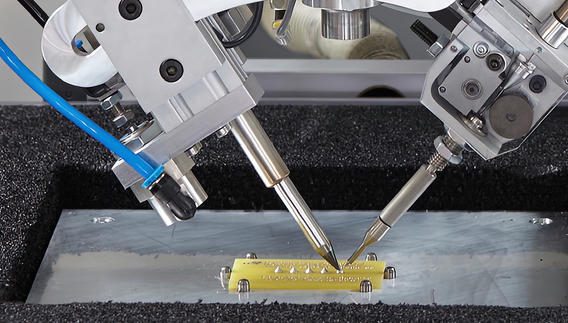

- The solder feeder is designed to be in close proximity to the workpiece (PCB), pulling the wire rather than pushing it through the feeder tube.

- The robust and sturdy construction ensures that no sudden movements or vibrations negatively affect the workpiece, the components or the tools.

- Working area allows maximum flexibility (Drawer height 100 mm).

Maximizing productivity, lowering cost

- A double drawer system allows continuous production thereby providing much higher process throughput, improving productivity and offering flexibility.

- The WTBR 1000 allows up to 50% cost saving versus hand soldering.

- Double drawer system for continuous production.

- LED illuminated camera enables high-precision soldering with superior quality control.

- “On point” solder feeder next to the iron smoothly pulls the solder wire through the tube.

Fully-enclosed system offers triple protection

- Being a fully-enclosed system, with integrated fume extraction, the WTBR 1000 Benchtop Robot allows our customers to achieve the highest level of safety: protecting the operator, the workpiece (PCB) and the machine.

- The fully-enclosed system provides a complete and CE-compliant solution to the customer.

Easy to learn and use software

- The WTBR 1000 is operated with easy to learn and use software, enabling operators to start using the unit comfortably and quickly.

- It is easy to switch from one operator to another, with minimum time lost and without unnecessary training expenses.

Triple protection. More safety. Less downtime.

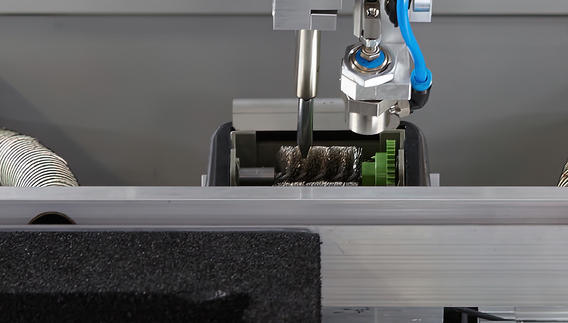

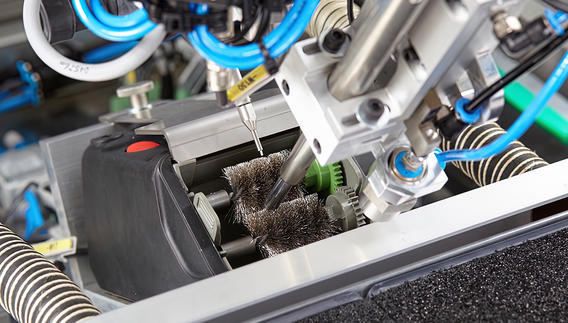

Integrated fume extraction system protects operator, workpiece, and equipment. The increased production of fine dust and hazardous vapors by soldering processes brings forth the need to protect technical systems and components, which are increasingly particle-sensitive, from contamination. And even more important: soldering byproducts are extremely dangerous to the operators, leading to respiratory and cardiovascular diseases. That is why we integrated a high performance and energy-efficient Weller fume extraction system into the WTBR 1000.

It retains or absorbs particles and gases preventing these from damaging the workpiece (PCB) and sensitive machine parts. Especially the camera lens is highly sensitive to damages caused by particles and gases. That means less wearout and less downtime negatively influencing manufacturing efficiency. Ultimately, the operators are fully protected from any exposure to hazardous substances.

WTBR 1000 software - quick and easy

The WTBR 1000 is operated by an easy to learn and use software to program special, customized settings for the operator‘s application. We tailored a special training method which will enable your operator to promptly start using the system unit. This also allows you to switch from one operator to another with minimum downtime and without having to spend additional resources for expensive training sessions.

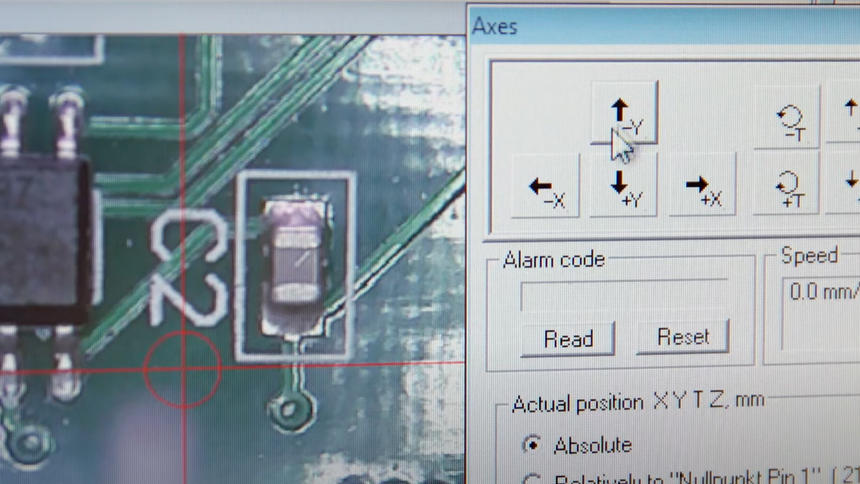

LED camera for superior process control and quality illumination

The integrated camera enables magnified, real-time and accurate inspection of process steps, facilitating high-precision soldering and superior quality control. It also facilitates teaching-in processes. The integrated LED lights are designed to ensure superior quality illumination, the optimum contrast between light and dark areas needed to provide high quality images, as well as lower energy consumption.

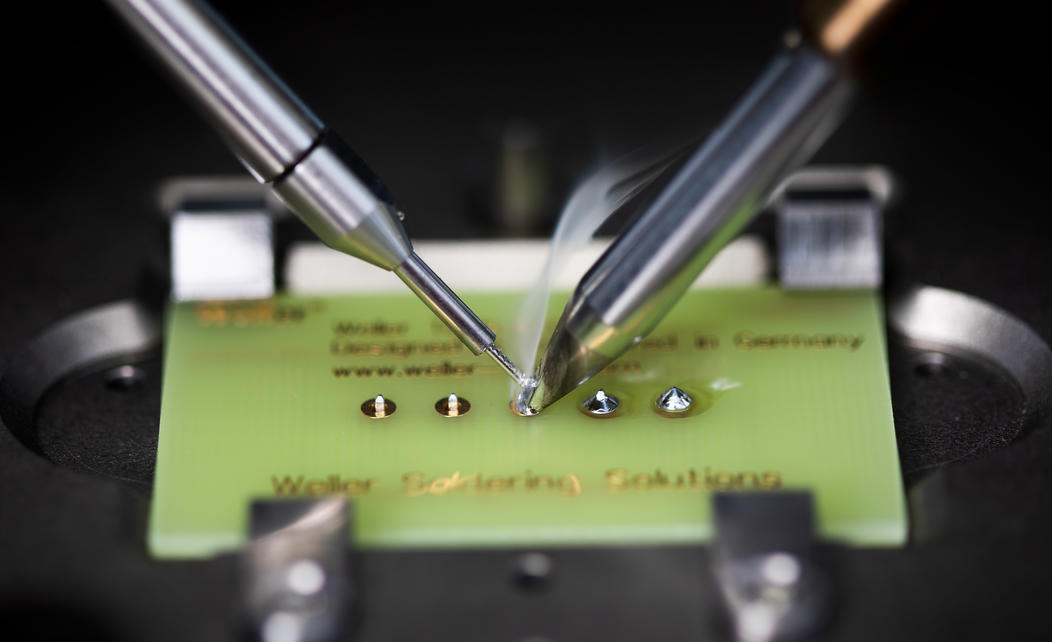

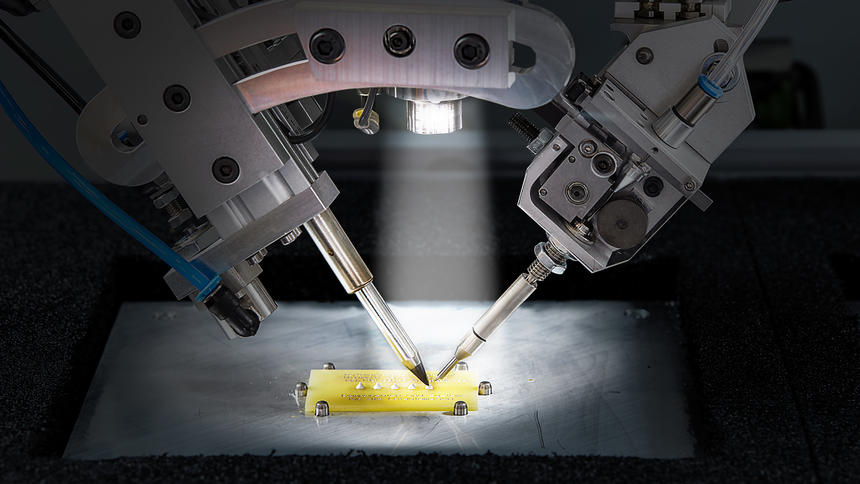

On point, smooth-pulling solder feeder

The newly designed, short distance feeder unit with wire pull system ensures the highest accuracy. The complete feed unit is built close to the soldering tip and the soldering points to be processed. The solder wire is smoothly pulled from the remote solder wire coil through a tube. This guarantees the smallest possible tolerance deviations and the highest solder joint quality.

The parameters of the required solder wire quantity can be programmed and controlled simply and quickly via the software wire feeder features:

- Dynamic feeding speed

- Wire pull system

- Short distance feeder to solder joint

- Smallest tolerances for wiring

- Closed loop speed control

- Stopage detection

- Precise programmable soldering quantity

- Easy coil change

Automated soldering - step-by-step