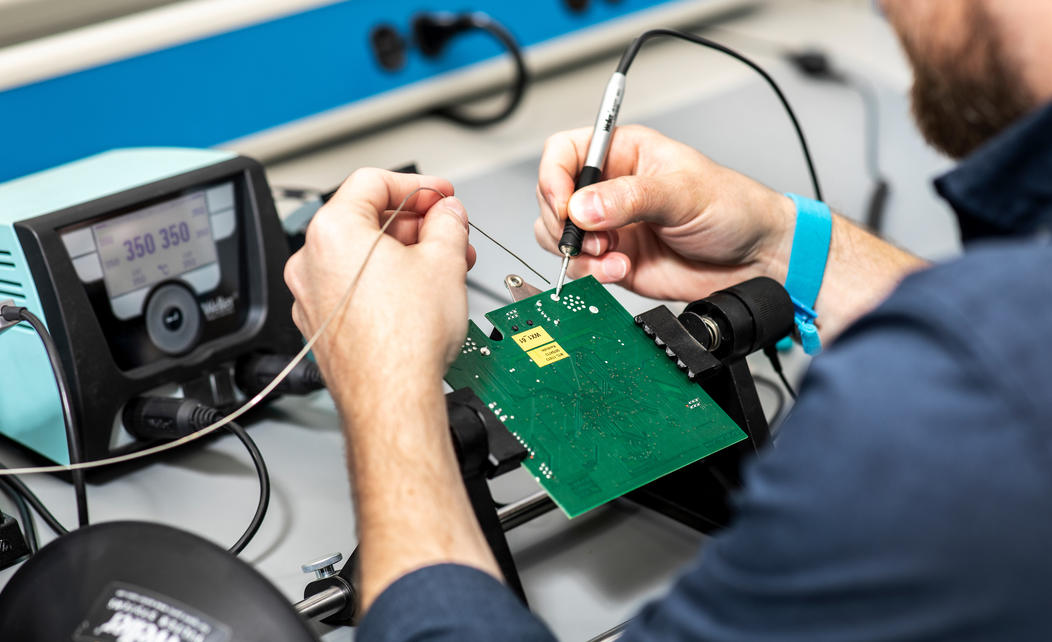

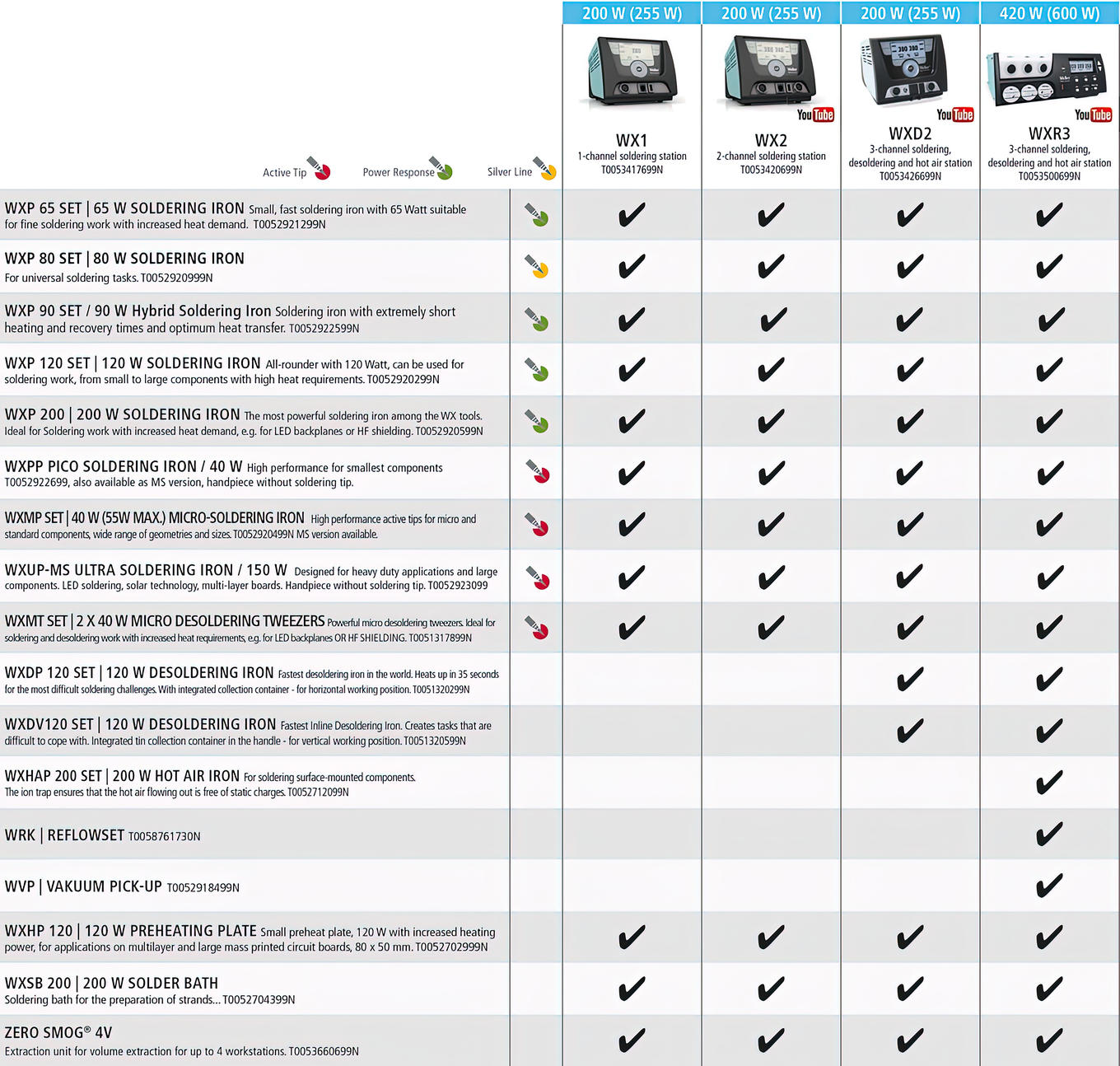

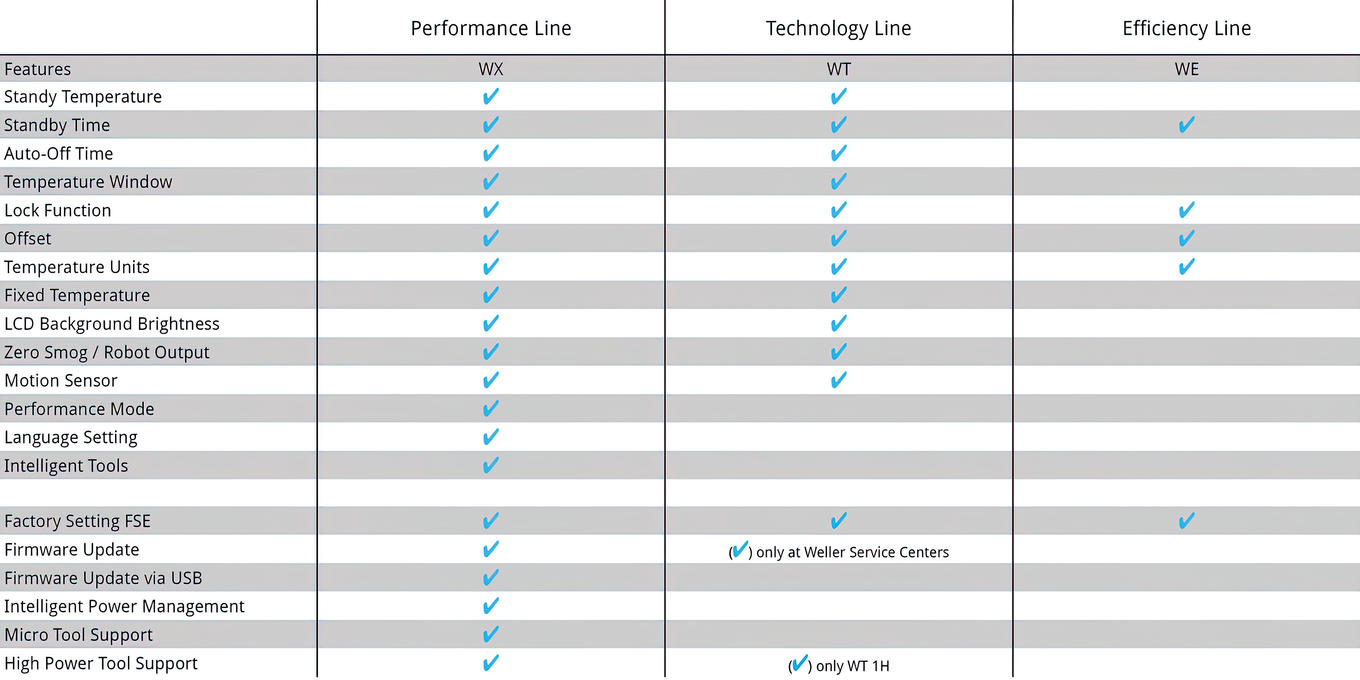

OUR WX TEAM

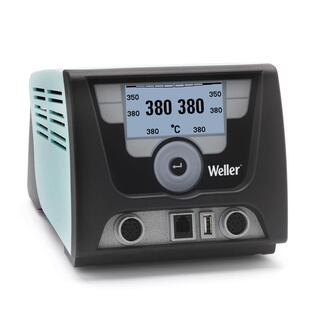

One platform – up to every challenge

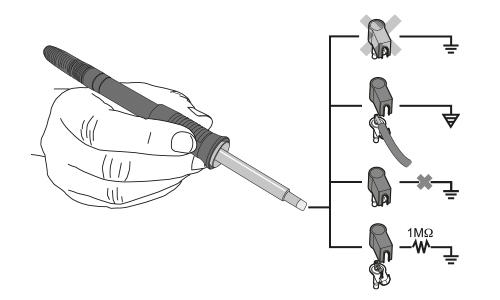

The five specialists from the Weller WX Team will solve all your problems to do with soldering, desoldering and the use of hot-air in your manufacturing process. The entire WX team offers full WX tool compatibility, tried-and-tested benchtop functions and all essential traceability features.